MIL-PRF-25508H

3.3 Filter. A filter with no more than a 10-micrometer nominal and 40-micrometer absolute rating

shall be installed between the manufacturer's plant system and the manifold used to fill the gas or liquid

containers for delivery.

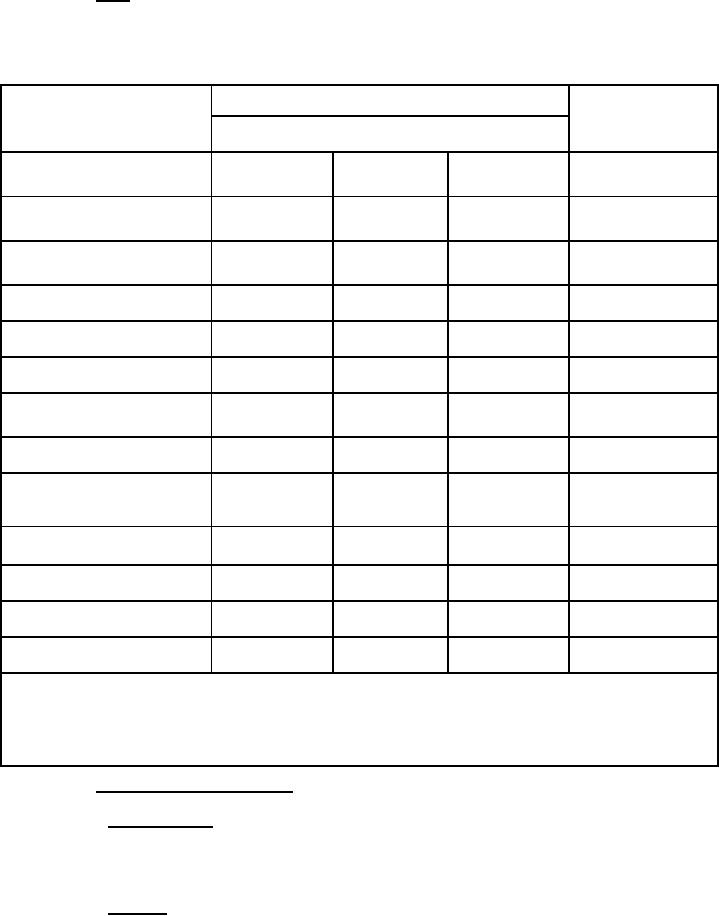

TABLE I. Grade limits for oxygen.

Grade

Test Method

A

B

F

Purity, percent by volume,

99.6

99.5

99.990

4.4.1

min

Impurities, ppm by

volume, max

4000

5000

100

4.4.1

Total hydrocarbons as

50

67.7

20

4.4.2

methane

Water

3

26.3

3

4.4.2

Methane

Note a

Note a

16

4.4.2

Ethane

Note a

Note a

2

4.4.2

Propane and higher

Note a

Note a

1

4.4.2

hydrocarbons as propane

Nitrous oxide

Note a

Note a

1

4.4.2

Halogenated

Note a

Note a

1

4.4.2

hydrocarbons

Carbon monoxide and

Note a

Note a

1

4.4.2

carbon dioxide

Other (N, Ar, Kr, etc.)

Note a

Note a

75

4.4.2

Odor

Note a

Note a

None

4.4.2

b

Particulate , mg/L, max

1.0

1.0

1.0

4.4.3

Notes:

a. No limit for this grade.

b. Applies to Type II product only. The particulate test requirement and limit may be deleted by the

procuring activity (see 6.2).

3.4 Filled containers (Type I only).

3.4.1 Filling Pressure. The container filling pressure shall not differ from that required by the

contract by more than 1.0% at 70°F when tested as specified in 4.5.1. In no case shall the filling pressure

exceed the rated service pressure of the container. Pressure-Temperature Filling Charts in CGA P-15

may be used.

3.4.2 Leakage. Cylinders shall not leak when tested according to 4.5.2.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business