MIL-PRF-27407D

filling pressure exceed the rated service pressure of the container. Pressure-Temperature Filling Charts in

CGA P-15 may be used.

3.4.2 Leakage. Cylinders shall not leak when tested according to 4.6.2.

3.4.3 Inspection and maintenance. Compressed gas cylinders shall be inspected, maintained

and charged according to 4.6.3.

4.

VERIFICATION

4.1 Points of inspection (see 6.2). Unless otherwise specified, acceptance tests shall be

conducted at the site of filling prior to shipment or departure.

4.2 Conformance inspection. Quality conformance tests shall consist of the following:

a. Individual tests (Type I only)................................ 4.2.1

b. Sampling tests .................................................... 4.2.2

4.2.1 Individual tests (Type I only). Each container shall be subjected to the following tests as

described under 4.6

a. Filling pressure .................................................... 4.6.1

b. Leakage .............................................................. 4.6.2

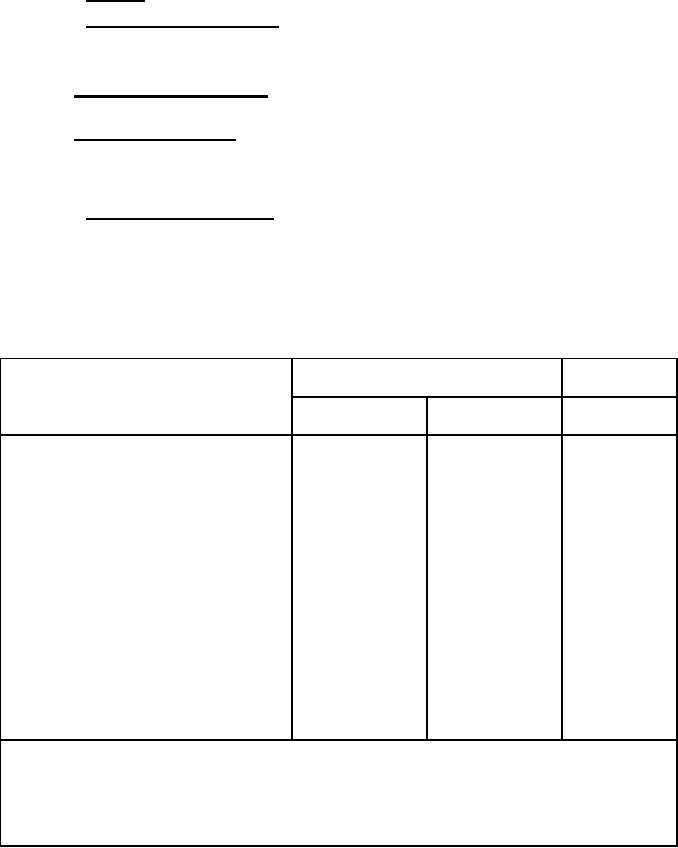

TABLE I. Grade limits for helium (Type I, gaseous only) 1

Grade

Test Method

A

B

Purity, % by vol, min

99.995

99.997

4.4.1

2

Impurities, ppm by vol, max

4.4.2

50

--

9

Water

4.4.2

9

1

Hydrocarbons (as methane)

4.4.2

5

3

Oxygen

4.4.2

3

5

Nitrogen + argon

4.4.2

14

23

Neon

4.4.2

23

1

Hydrogen

4.4.2

1

2

--

Carbon dioxide

4.4.2

1

2

--

Carbon monoxide

4.4.2

1

Notes:

1. For Type II requirements see 4.5. When using vent gas analysis, the analysis shall conform to

Grade A or B requirements, as specified in the contract.

2. No limit for this grade; minimum purity shall be met.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business