MIL-PRF-27415C

3.4 Filled containers (Type I only).

3.4.1 Pressure. The container filling pressure (see 6.2) shall not differ from that required by the

contract by more than 1.0% at 21°C (70°F) when tested as specified in 4.5.1. In no case shall the filling

pressure exceed the rated service pressure of the container.

3.4.2 Leakage. Cylinders shall not leak when tested according to 4.5.2.

3.4.3 Inspection and maintenance. Compressed gas cylinders shall be inspected, maintained,

and charged according to 4.5.3.

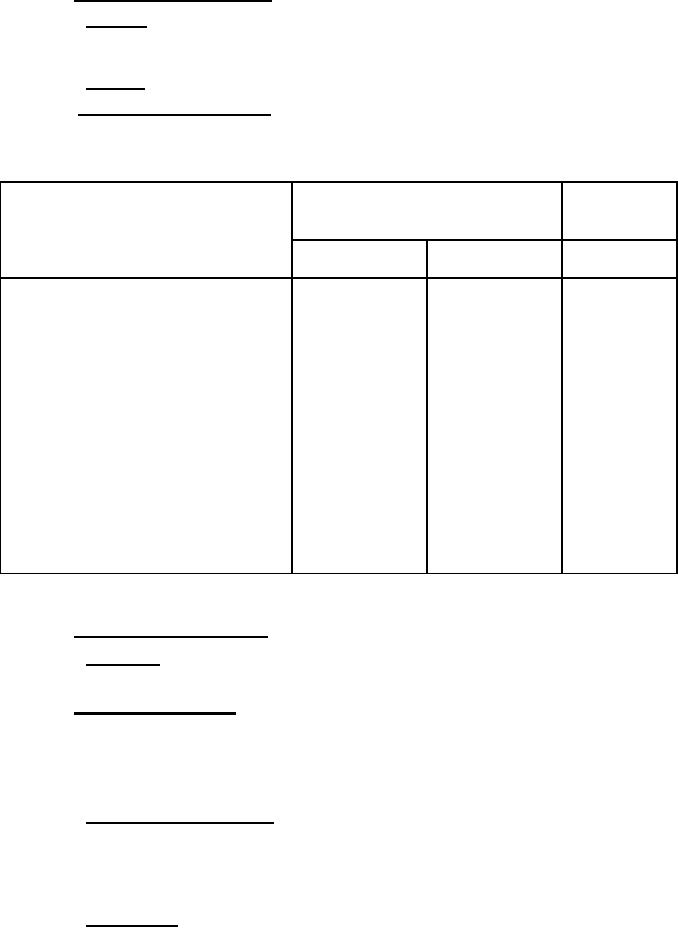

TABLE I. Limits for argon

Test

Composition

Grade

Paragraph

A

B

Purity, % by volume, min

99.998

99.985

4.4.1

Impurities

Water, ppm by volume, max

3.5

23

4.4.2

Dewpoint, °C (°F)

-68 (-90)

-54 (-65)

4.4.2

Oxygen, ppm by volume, max

2

50

4.4.2

Hydrogen, ppm by volume, max

2

50

4.4.2

Nitrogen, ppm by volume, max

10

50

4.4.2

Total hydrocarbons (as methane),

0.5

Not specified

4.4.2

ppm by volume, max

Carbon dioxide, ppm by volume, max

0.5

Not specified

4.4.2

4.

VERIFICATION

4.1 Points of inspection (see 6.2).

4.1.1 Containers. Unless otherwise specified, acceptance tests shall be conducted at the site of

filling prior to shipment or departure.

4.2 Conformance inspection. Quality conformance tests shall consist of the following:

a. Individual tests (Type I only) ................................ 4.2.1

b. Sampling tests .................................................... 4.2.2

4.2.1 Individual tests (Type I only). Each container shall be subjected to the following tests as

described under 4.5:

a. Filling pressure .................................................... 4.5.1

b. Leakage .............................................................. 4.5.2

4.2.2 Sampling test. The number of argon containers shall be selected in accordance with

Table II and subjected to the tests required by Table I.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business