MIL-PRF-87896A

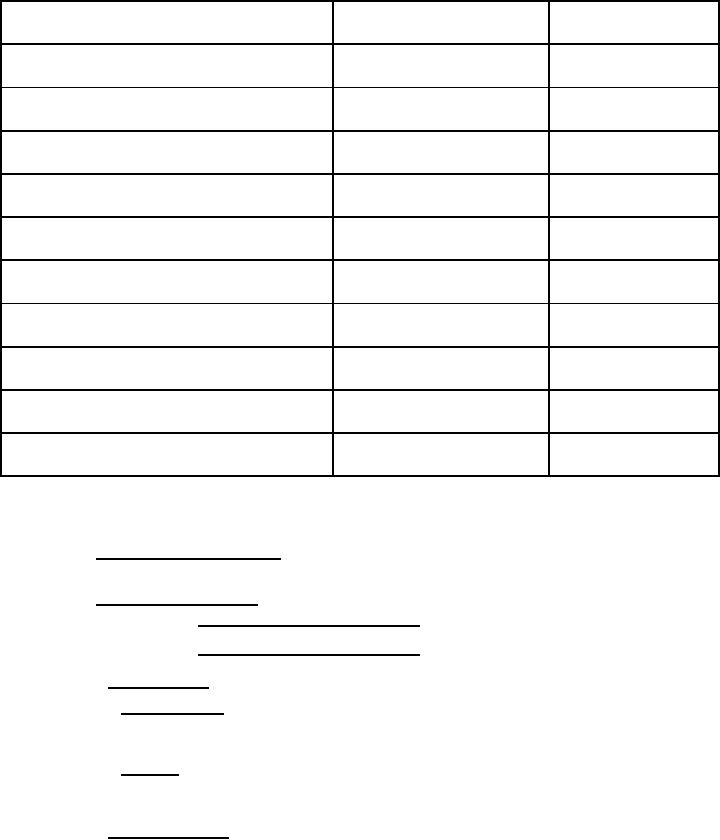

TABLE I. Chemical composition and physical properties.

Composition

Limit

Test Paragraph

Purity, Nitrogen trifluoride (NF3), % Vol (min)

99.0

4.5.1

Tetrafluoromethane (CF4), % Vol (max)

0.5

4.5.2

Carbon Dioxide (CO2), % Vol (max)

0.1.

4.5.2

Nitrous Oxide (N2O), % Vol (max)

0.1

4.5.2

Sulfur Hexafluoride (SF6), % Vol (max)

0.1

4.5.2

Oxygen (O2) + Argon (Ar), % Vol (max)

0.1

4.5.3

Nitrogen (N2), % Vol (max)

0.1

4.5.3

Carbon Monoxide (CO), % Vol (max)

0.1

4.5.3

Total Reactive Fluoride (as HF), % Vol (max)

0.1

4.5.4

Water (H2O), ppmv (max)

5

4.5.5

4. VERIFICATION

4.1 Classification of inspections. The inspections shall be classified as conformance

inspections.

4.2 Conformance inspection. Quality conformance tests shall consist of the following:

a. Individual tests

4.2.1

b. Sampling tests

4.2.2

4.2.1 Individual tests. Each container shall be subjected to the following tests:

4.2.1.1 Filling pressure. The container shall be tested for proper filling pressure by using an

ASME B40.1 type pressure gauge with a minimum of a 2A accuracy grade; calibration must be NIST

traceable.

4.2.1.2 Leakage. Each container shall be tested for leaks at the neck threads, stem packing,

and pressure relief device of the valve with leak detection fluid. Valve seat leakage shall be tested by

means of a tube from the valve outlet to a container of liquid.

4.2.2 Sampling for tests. When more than one container (cylinders or tubes) is filled from the

same lot, the number of containers selected for sampling from that lot shall be IAW Table II. The first and

last containers to be filled within a given lot shall be sampled. Other samples may be selected at random.

The propellant from each container sampled shall constitute a separate sample.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business