MIL-PRF-27404D

2.4 Order of precedence. Unless otherwise noted herein or in the contract, in the event of a

conflict between the text of this document and the references cited herein (except for related specification

sheets), the text of this document takes precedence. Nothing in this document, however, supersedes

applicable laws and regulations unless a specific exemption has been obtained.

3. REQUIREMENTS

3.1 Chemical and physical properties. The chemical and physical properties of the propellant

shall conform to those listed in Table I when tested in accordance with the applicable test methods.

3.2 Limiting values. The following applies to all specified limits in this specification: For

purposes of determining conformance with these requirements, an observed value or a calculated value

shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification

limit according to the rounding-off method of ASTM Practice E29, Standard Practice for Using Significant

Digits in Test Data to Determine Conformance with Specifications.

3.3 Filter. A filter with a rating of at least 10 micrometer (Ám) nominal and 40 Ám absolute rating

shall be installed between the manufacturer's plant system and the container to be filled for delivery.

3.4 Qualitative. The propellant shall be a clear and colorless homogeneous liquid when

examined visually by transmitted light (a trace yellow/straw to green discoloration is allowed when

compared to a sample bottle containing purified water).

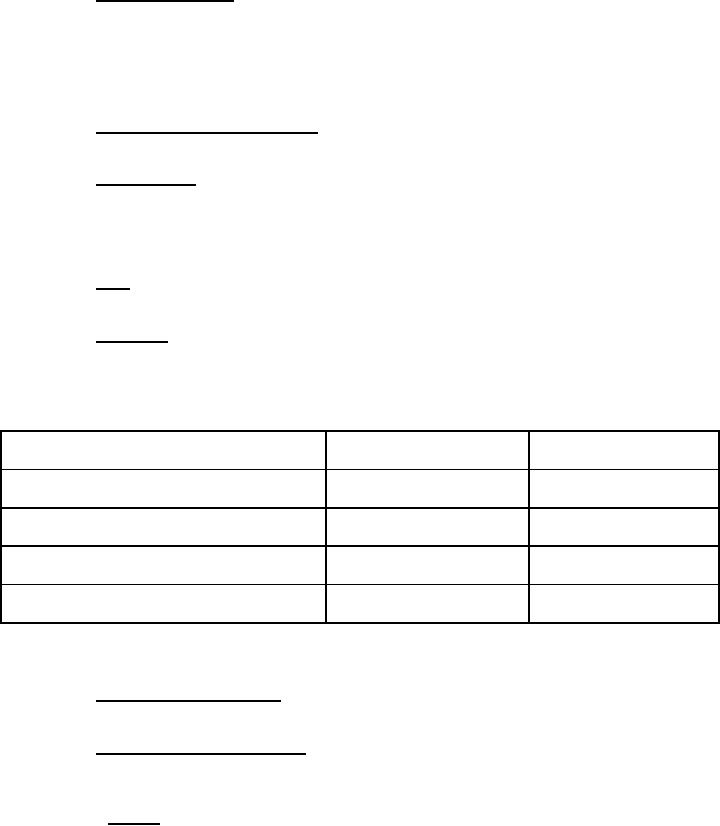

TABLE I. Chemical and physical properties.

Properties

Limits

Test Paragraph

Monomethylhydrazine (% by wt)

98.3

4.3.2

Water (% by wt)

1.5 max

4.3.2

Non-volatile residue (mg/L)

10 max

4.3.3

Particulate (mg/L)

10 max

4.3.4

4. VERIFICATION

4.1 Classification of inspections. The inspections shall be classified as quality conformance

inspections.

4.2 Quality conformance inspection. Unless otherwise specified (6.2), each filled shipping

container shall be considered a lot and shall be sampled. Each sample shall be subjected to the visual

examination described in 4.3.1 for conformance to 3.4 and to the tests specified in Table I.

4.2.1 Sample. A sample consists of not less than 600 milliliters (mL) of propellant. Unless

otherwise specified, quality conformance tests shall be made on the sample of propellant taken directly

from the shipping container. When required, the sample shall be forwarded to a laboratory designated by

the procuring activity for subjection to the quality conformance tests specified herein. The bottle intended

for sampling shall be specially cleaned and handled according to the procedure described in ASTM

D2276 Section 10 with the exception listed 4.3.4d.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business