MIL-DTL-87107E

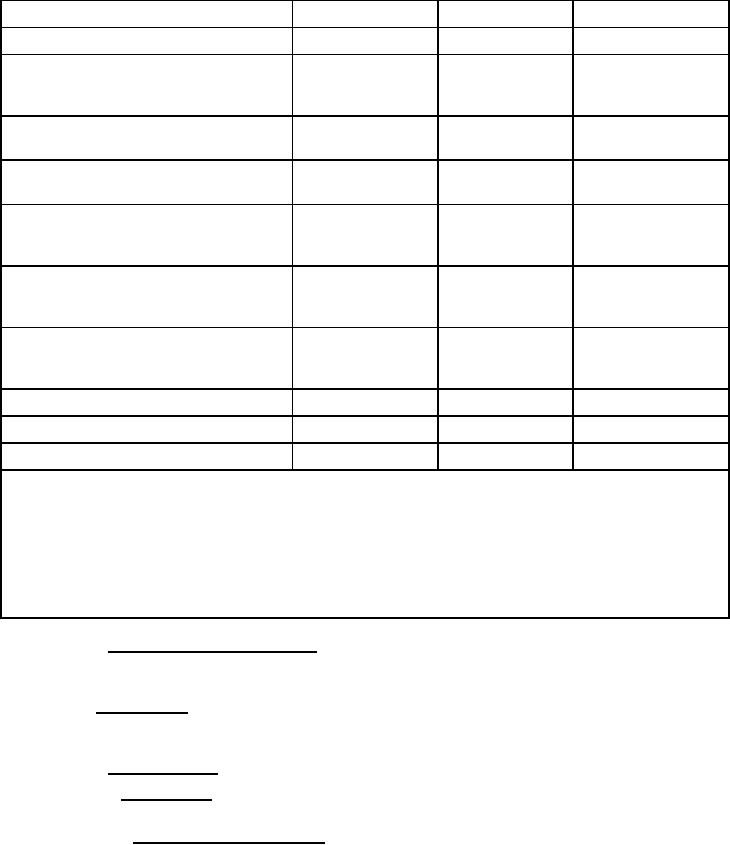

TABLE I. Chemical and physical requirements and test methods.

Property

Min

Max

ASTM Standards

1

Color, Saybolt

+25

D156 or D6045

Chemical Analysis, wt percent

exo-tetrahydrodicyclopentadiene

98.5

100.0

2

other hydrocarbons

1.5

1

Flash point, °C (°F)

54.4 (130)

D56, D93 , or

D3828

Density, 15 °C, kg/L (API Gravity)

0.934 (20.0)

0.943 (18.5)

D1298 or

1

D4052

2

Viscosity, mm /s at °C (°F)

D445

-54 (-65)

40

-18 (0)

10

Net heat of combustion

D240 or D4809

MJ/kg (Btu/lb)

42.1 (18,100)

MJ/m (Btu/gal)

39,400 (141,500)

4

Thermal stability

D3241

change in pressure drop, mm Hg

10

heater tube deposit visual rating

less than code 3

5

Existent gum, mg/100 mL

5.0

D381

Particulate matter, mg/L

1.0

D2276 or D5452

6

FSII, vol. percent

0.10

0.15

D5006

Notes

1. Referee test method.

2. Test procedure and required equipment outlined in Appendix A.

3. This is for reference only, not a requirement.

4. See 4.5.1.1 for ASTM D3241 test conditions and test limits.

5. If air is used instead of steam while performing ASTM D381, it must be reported. In the case of a

failure with air, the sample must be retested using steam.

6. As required by user, see 3.3.2.

4.4.3 Examination of filled containers. Samples taken as specified in 4.2.2.2 shall be examined

for conformance to MIL-STD-290 with regard to fill, closure, sealing, leakage, packaging, packing, and

markings. Any container having one or more defects under the required fill shall be rejected.

4.5 Test methods. Tests to determine conformance to chemical and physical requirements shall

be conducted in accordance with the applicable ASTM standards, or in the case of unique requirements,

the test procedures as outlined in Table I and described in the attached Appendix.

4.5.1 Thermal stability.

4.5.1.1 ASTM D3241. The thermal stability test shall be conducted and the tube shall be rated

using ASTM D 3241 (JFTOT).

4.5.1.1.1 ASTM D3241 test conditions.

a.

Heater tube temperature at maximum point: 300°C (572°F).

b.

Fuel system pressure: 3.43 MPa (500 psig).

c.

Fuel flow rate: 3.0 ml/minute.

d.

Test duration: 150 minutes.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business