MIL-DTL-87173B(USAF)

3.2.3 Fuel system icing inhibitor. Fuel system icing inhibitor shall be used only at the request of the

User. If requested by the User, the inhibitor shall conform to MIL-I-85470.

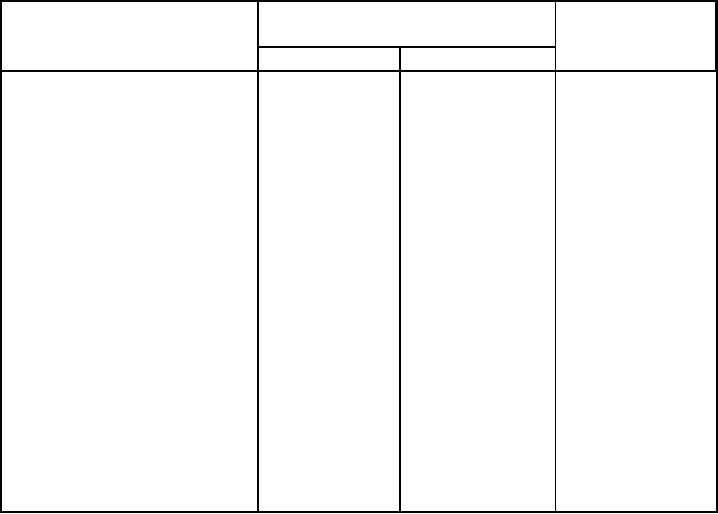

TABLE I. Chemical and physical requirements and test methods.

Priming

ASTM

Fluid

Standards

Property

Minimum

Maximum

4

Color, Saybolt

+25

D156 , D6045

1

Chemical composition, wt, percent

methylcyclohexane

10.0

15.0

exo-

83.5

90.0

tetrahydrodi(cyclopentadiene)

1.5

other hydrocarbons

4

Flash point, °C (°F)

16 (60)

27 (80)

D93 , D3828

D1298, D4052 4

Specific gravity, (60/60F)

0.900

0.930

Freezing point, °C (°F)

-54 (-65)

D2386

Viscosity, centistokes at -54 °C

40

D445

D240, D2382

Net heat of combustion

42.1

MJ/kg (Btu/lb)

(18,100)

D3241 2

Thermal stability change in

pressure drop, mm Hg

10

heater tube deposit visual rating

< Code 3

Existent gum, mg/100 mL

5

D381

Particulate matter, mg/liter

1.0

D2276, D5452

D5006 3

0.10

0.15

Fuel system icing inhibitor, volume

percent

1

Test shall be performed using appendix A or appendix C.

2

See 4.5.3 for ASTM D3241 test conditions and test limits.

3

Use proper scale of refractometer.

4

Referee Test Method

3.3 Performance. The priming fluid shall satisfy the performance requirements as specified in the tests

of section 4, herein.

3.4 Workmanship. The priming fluid shall be visually free from undissolved water, sediment, or

suspended matter and shall be clean and bright at the ambient temperature or at 21°C (70 °F), whichever

is higher.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business